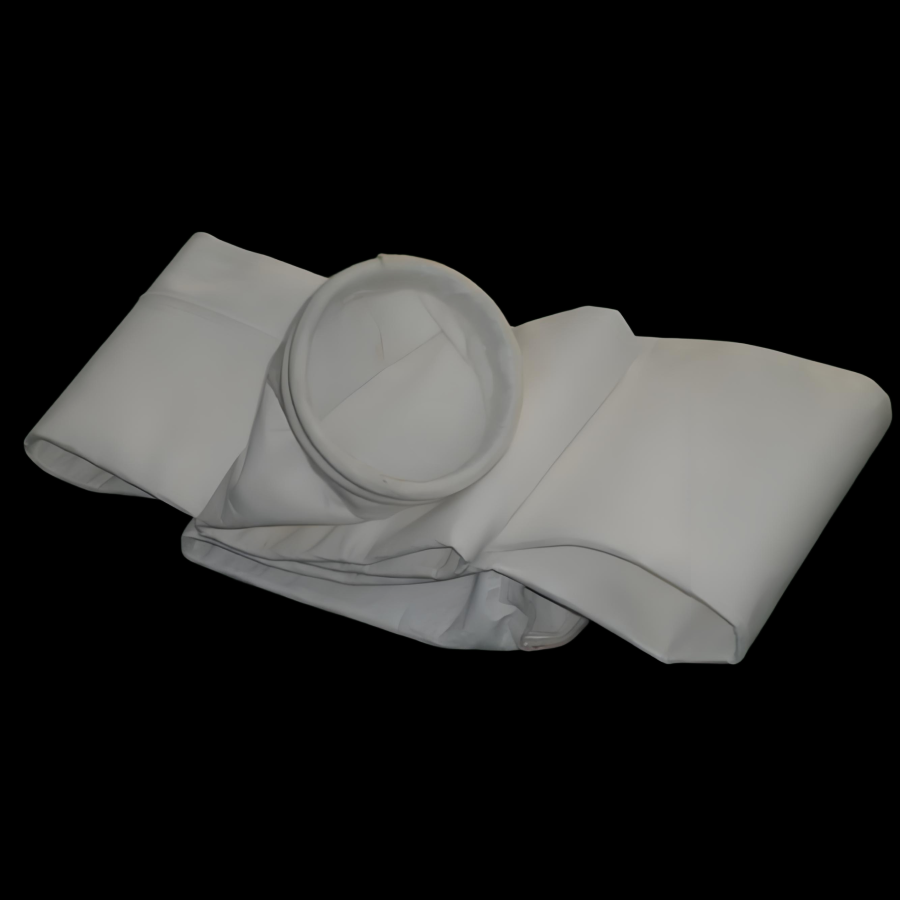

Filter Bags

Key Features

- Operating temperature up to 260°C (500°F)

- Chemical resistant PTFE construction

- Superior air permeability (120-250 m³/m²/min)

- Multi-layer composite structure

- Advanced surface treatment technology

Technical Specifications

| Product Name | Technical Term | Weight | Thickness | Peak Temperature | Operating Temperature | Air Permeability | Post-Treatment | Material |

|---|---|---|---|---|---|---|---|---|

| Normal Temperature Filter Bag | Needle-Punched Felt | 500 g/m² | 1.8 mm | 150°C (302°F) | 130°C (266°F) | 130 | Singeing, Calendaring, or PTFE Coating | Polyester Short/Long Fiber Felt |

| Oil and Water Repellent Needle Felt | 550 g/m² | 1.9 mm | 150°C (302°F) | 130°C (266°F) | 200 | Singeing, Calendaring, or PTFE Coating | Polyester Fiber Felt | |

| High Temperature Filter Bag | Polyimide Needle Felt | 550 g/m² | 2.7 mm | 260°C (500°F) | 240°C (464°F) | 250 | PTFE Impregnation, PTFE Coating | P84 |

| Fiberglass Needle Felt | 750 g/m² | 2.7 mm | 300°C (572°F) | 260°C (500°F) | 100 | PTFE Lamination | Fiberglass | |

| Medium Temperature Filter Bag | PPS Needle Felt | 500 g/m² | 1.6 mm | 200°C (392°F) | 160°C (320°F) | 217 | PTFE Impregnation, PTFE Coating | PPS Fiber Felt |

| PTFE Needle Felt | 700 g/m² | 1.7 mm | 260°C (500°F) | 240°C (464°F) | 120 | PTFE Impregnation, Lamination, Coating | PTFE Fiber and PTFE Base Fabric |

Industrial-Grade Stainless Steel Filter Bags

Superior durability meets precision filtration

Industrial Filtration Excellence: Filter Bags

Advanced Technology for Critical Applications

- Withstands extreme temps up to 260°C

- Maintains stability under heat stress

- Zero deformation at peak temperatures

- 2x longer lifecycle vs standard bags

- Reduced replacement frequency

- Lower total ownership cost

- 99.9% particle capture rate

- Consistent performance output

- Minimal pressure drop

- Complete acid/alkali resistance

- No material degradation

- Suitable for aggressive environments

- Reduced maintenance downtime

- Lower energy consumption

- Minimal replacement needs

Industrial Applications

Engineered Solutions Across Critical Industries

FAQs

What determines the service life of filter bags?

Filter bag life primarily depends on operating conditions and maintenance practices. Under standard conditions, our bags typically last 12-24 months. Key factors affecting lifespan include operating temperature, chemical exposure, maintenance frequency, and particle load characteristics. Regular monitoring of differential pressure and proper maintenance can significantly extend service life.

How do I select the right filter bag for my application?

Selection should be based on your specific process requirements. We evaluate five critical factors: operating temperature, chemical compatibility, particle size distribution, air-to-cloth ratio, and system pressure limitations. Our technical team can help analyze these parameters to recommend the optimal solution for your operation.

What determines the service life of filter bags?

Filter bag life primarily depends on operating conditions and maintenance practices. Under standard conditions, our bags typically last 12-24 months. Key factors affecting lifespan include operating temperature, chemical exposure, maintenance frequency, and particle load characteristics. Regular monitoring of differential pressure and proper maintenance can significantly extend service life.

How do I select the right filter bag for my application?

Selection should be based on your specific process requirements. We evaluate five critical factors: operating temperature, chemical compatibility, particle size distribution, air-to-cloth ratio, and system pressure limitations. Our technical team can help analyze these parameters to recommend the optimal solution for your operation.

What maintenance is required for optimal performance?

Effective maintenance includes regular differential pressure monitoring, scheduled cleaning cycles, and periodic visual inspections. We recommend maintaining a performance log to track key metrics and optimize cleaning intervals. This proactive approach helps prevent unexpected downtime and extends filter life.

When should I replace my filter bags?

Key replacement indicators include:

- Sustained high differential pressure that doesn't reduce after cleaning

- Visible damage or wear during inspection

- Decreased collection efficiency

- Exceeded recommended service hours

- Failed integrity tests

Early detection of these signs helps prevent system inefficiencies and product loss.

What's the proper installation procedure?

Proper installation is crucial for optimal performance. This includes:

- Ensuring correct cage fitment

- Proper tensioning of the bag

- Secure sealing at all connection points

- Verification of proper alignment

Our installation guide provides detailed steps, and technical support is available if needed.

How do temperature fluctuations affect performance?

Temperature variations can significantly impact filter performance. Our bags are designed to maintain structural integrity and filtration efficiency within their specified temperature range. The PTFE construction ensures consistent performance even with temperature fluctuations up to 260°C without compromising chemical resistance or filtration efficiency.

What cleaning methods do you recommend?

We endorse several cleaning methods based on your specific application:

- Pulse-jet cleaning for continuous operation

- Reverse air cleaning for sensitive materials

- Mechanical shaking for certain applications

Our technical team can help determine the most effective cleaning strategy for your system.

Can you provide customized solutions?

Absolutely. We offer customization in:

- Size specifications to fit your housing

- Material selection for specific chemical resistance

- Surface treatments for enhanced performance

- Special finishes for unique applications

Each custom solution is engineered to meet your exact requirements.

What warranty coverage is included?

Our comprehensive warranty covers:

- Material defects and manufacturing quality

- Performance guarantees based on specifications

- Technical support during installation

- Ongoing operational assistance

Specific warranty terms are provided with each order.

How can I optimize my filter bag performance?

Performance optimization involves:

- Following recommended maintenance schedules

- Monitoring system parameters regularly

- Operating within specified conditions

- Implementing proper cleaning procedures

- Engaging with our technical support for periodic reviews