304 Stainless Steel Filter Bag

Key Features

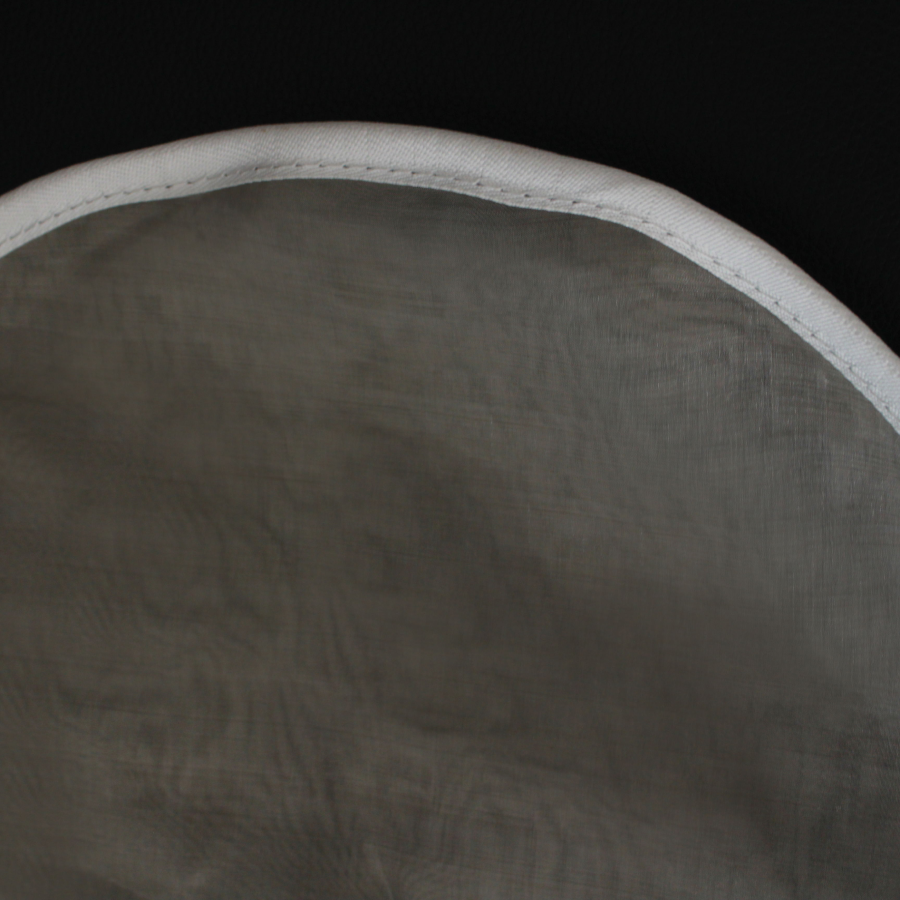

- Precision-welded seam construction for maximum integrity

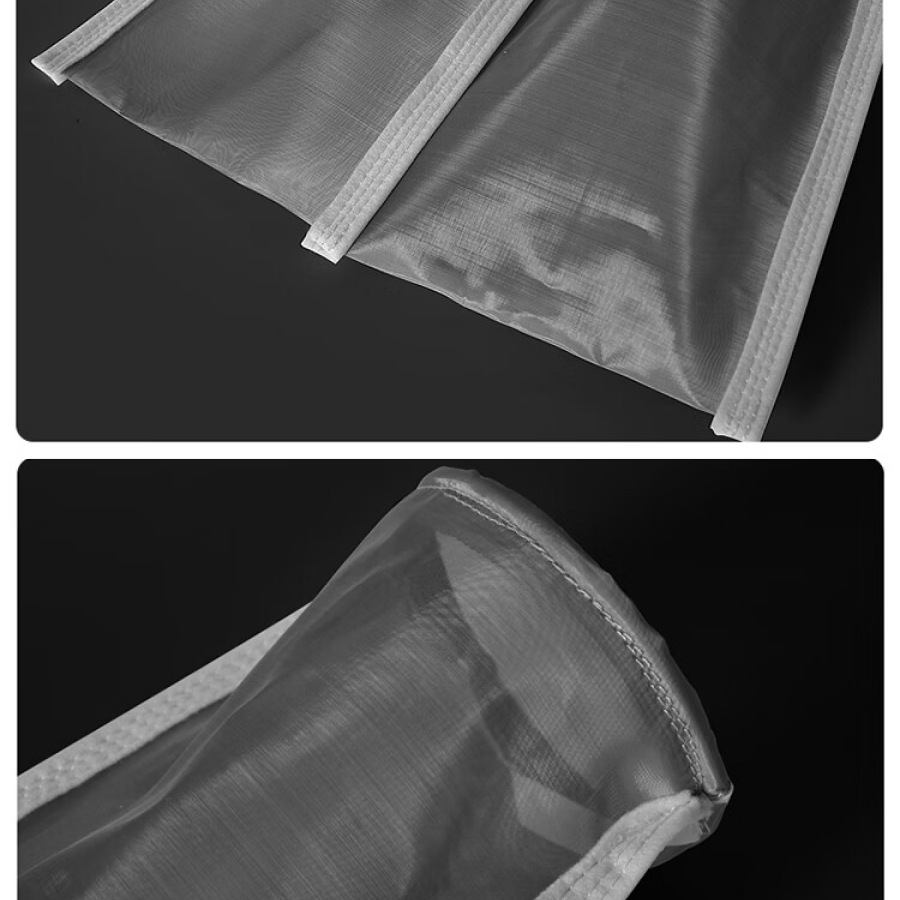

- Industrial-grade 304 stainless steel mesh construction

- Superior resistance to:

Corrosion

- High temperatures

- Chemical attack

- Mechanical stress

- Temperature resistance: Up to 800°F (427°C)

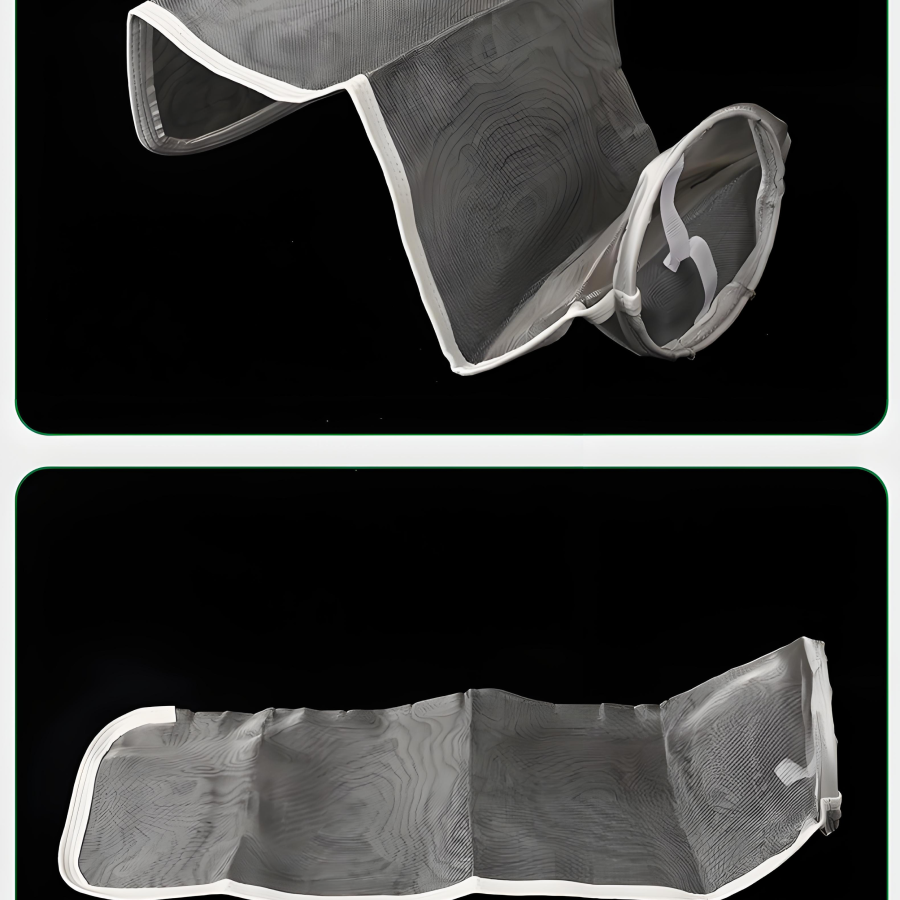

- Available with plastic or steel ring options

- High throughput capacity

- Excellent cleanability and reusability

Technical Specifications

| Parameter | Details | |

|---|---|---|

| Product Type | Stainless Steel Filter Bag | |

| Ring Options | Plastic Ring, Steel Ring | |

| Resistance | Corrosion Resistant, Alkali Resistant | |

| Applications | Edible Oil, Beverages, Fruit Juice, Herbal Tea, Wine Lees, Coatings, Paint | |

| Mesh | 20 Mesh, 30 Mesh, 40 Mesh, 50 Mesh, 60 Mesh, 80 Mesh, 100 Mesh, 120 Mesh, 150 Mesh, 200 Mesh, 250 Mesh, 300 Mesh, and 400 Mesh | |

| Micron Rating (μm) | 750 μm, 500 μm, 400 μm, 350 μm, 300 μm, 200 μm, 150 μm, 130 μm, 100 μm, 75 μm, 60 μm, 50 μm, and 38 μm | |

| Model | Diameter (inch) | Length (inch) | Volume (L) | Precision (Mesh) | Max Flow Rate (m³/h) | Filtration Area (m²) | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size #1 | 7.09 | 16.93 | 8 | 20, 30, 40, 50, 60, 80, 100, 120, 150, 200, 250, 300, 400 | 20 | 0.25 | |||||||||||||||||||||

| Size #2 | 7.09 | 31.89 | 17 | 20, 30, 40, 50, 60, 80, 100, 120, 150, 200, 250, 300, 400 | 40 | 0.5 | |||||||||||||||||||||

| Size #3 | 4.13 | 9.06 | 1.3 | 20, 30, 40, 50, 60, 80, 100, 120, 150, 200, 250, 300, 400 | 6 | 0.09 | |||||||||||||||||||||

| Size #4 | 4.13 | 14.96 | 2.5 | 20, 30, 40, 50, 60, 80, 100, 120, 150, 200, 250, 300, 400 | 12 | 0.16 | |||||||||||||||||||||

| Size #5 | 5.91 | 21.65 | 7 | 20, 30, 40, 50, 60, 80, 100, 120, 150, 200, 250, 300, 400 | 18 | 0.3 | |||||||||||||||||||||

| Mesh | Micron Rating (μm) | |

|---|---|---|

| 20 Mesh | 750 μm | |

| 30 Mesh | 500 μm | |

| 40 Mesh | 400 μm | |

| 50 Mesh | 350 μm | |

| 60 Mesh | 300 μm | |

| 80 Mesh | 200 μm | |

| 100 Mesh | 150 μm | |

| 120 Mesh | 130 μm | |

| 150 Mesh | 100 μm | |

| 200 Mesh | 75 μm | |

| 250 Mesh | 60 μm | |

| 300 Mesh | 50 μm | |

| 400 Mesh | 38 μm | |

Industrial-Grade Stainless Steel Filter Bags

Superior durability meets precision filtration

Industrial-Grade 304 Stainless Steel Filter Bags

High-Performance Industrial Liquid Filtration | Reusable Design | Temperature Resistant to 800°F

- Industrial-grade 304 stainless steel construction

- Stronger than plastic alternatives (PP/PE/Nylon)

- Maximum temperature resistance: 800°F

- Load capacity: 13.2 lbs (6 kg)

- 13 mesh options (20-400 mesh)

- Micron ratings: 38-750μm

- Consistent particle retention

- Optimal flow distribution

- 5 standard sizes available

- Flow rates: 6-40 m³/h

- Filter area: 0.09-0.50 m²

- Fits various housing requirements

- Excellent corrosion resistance

- Superior chemical compatibility

- Rigid welded seam construction

- Extended service lifetime

- Easily cleanable and reusable

- Minimal maintenance required

- Higher pressure tolerance

- Wide application range: oils, beverages, chemicals

Industrial Applications

FAQs

What are the main applications for these filter bags?

These bags are designed for multiple industrial applications including:

- Food-grade filtration (edible oils, beverages)

- Beverage processing (fruit juice, herbal tea)

- Industrial coatings and paints

- Wine production (wine lees filtration)

What size options are available?

We offer 5 standard sizes:

- Size #1: 8L capacity, 20 m³/h flow rate

- Size #2: 17L capacity, 40 m³/h flow rate

- Size #3: 1.3L capacity, 6 m³/h flow rate

- Size #4: 2.5L capacity, 12 m³/h flow rate

- Size #5: 7L capacity, 18 m³/h flow rate

What filtration precision levels are available?

We offer 13 mesh options ranging from 20 to 400 mesh:

- Coarse filtration: 20-60 mesh (750-300μm)

- Medium filtration: 80-150 mesh (200-100μm)

- Fine filtration: 200-400 mesh (75-38μm)

What are the key durability features?

Our filter bags feature:

- Corrosion and alkali resistant construction

- Choice of plastic or steel ring

- Reusable design

- Industrial-grade 304 stainless steel material

How do I choose the right mesh size?

Select based on your particle size requirements:

- Larger particles (>300μm): 20-60 mesh

- Medium particles (100-200μm): 80-150 mesh

- Fine particles (<100μm): 200-400 mesh

What is the cleaning and maintenance process?

The bags are designed for easy maintenance:

- Can be cleaned with industrial cleaners/solvents

- Suitable for ultrasonic cleaning

- Reverse flow cleaning compatible

- Regular inspection recommended for mesh integrity

- Do not turn inside out during cleaning

What is the typical service life?

Under proper maintenance:

- Multiple reuse cycles possible

- Extended lifetime compared to plastic filters

- Typical lifespan depends on application intensity

- Regular cleaning extends service life

- Recommended replacement when flow rate significantly decreases

What are the temperature and pressure limitations?

Performance specifications include:

- Maximum temperature: 800°F (427°C)

- Higher pressure tolerance than plastic filters

- Maximum load capacity: 13.2 lbs (6 kg)

- Suitable for high-temperature applications

- Maintains integrity under pressure fluctuations

How do I select the right model?

Consider these factors:

- Required flow rate (6-40 m³/h)

- Process liquid type

- Operating temperature

- Particle size to be filtered

- Available housing space

Are there any special handling requirements?

Important handling notes:

- Avoid sharp objects that could damage mesh

- Store in clean, dry environment

- Handle rings with care during installation

- Follow proper installation orientation

- Regular inspection for optimal performance