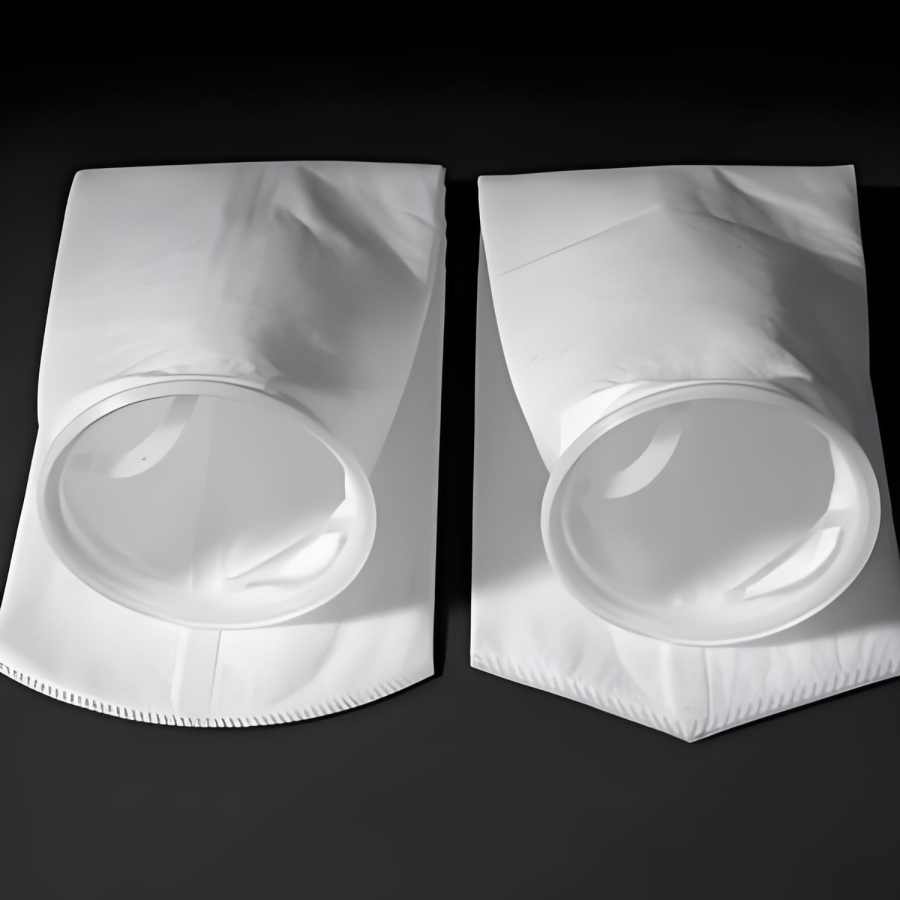

Polyester (PE) Filter Bags

Key Features

- Advanced 5-line needle construction for enhanced sealing

- Heat-treated finish for improved durability

- Superior resistance to:

- Abrasion

- Acids

- Alkaline solutions - Temperature resistance: -20°C to 130°C

- Available with plastic or steel rings for optimal sealing

- High dirt-holding capacity

- Excellent chemical compatibility

Technical Specifications

| Model | Diameter (inch) | Length (inch) | Volume (L) | Precision (Mesh) | Max Flow Rate (m³/h) | Filtration Area (m²) | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size #1 | 7.09 | 16.93 | 8 | 0.1, 0.5, 1, 5, 10, 25, 50, 100, 150, 200, 300, 500 | 20 | 0.25 | |||||||||||||||||||||

| Size #2 | 7.09 | 31.89 | 17 | 0.1, 0.5, 1, 5, 10, 25, 50, 100, 150, 200, 300, 500 | 40 | 0.5 | |||||||||||||||||||||

| Size #3 | 4.13 | 9.06 | 1.3 | 0.1, 0.5, 1, 5, 10, 25, 50, 100, 150, 200, 300, 500 | 6 | 0.09 | |||||||||||||||||||||

| Size #4 | 4.13 | 14.96 | 2.5 | 0.1, 0.5, 1, 5, 10, 25, 50, 100, 150, 200, 300, 500 | 12 | 0.16 | |||||||||||||||||||||

| Size #5 | 5.91 | 21.65 | 7 | 0.1, 0.5, 1, 5, 10, 25, 50, 100, 150, 200, 300, 500 | 18 | 0.3 | |||||||||||||||||||||

Need Polyester Filter Bags for Your Process?

From standard sizes to custom requirements

Polyester (PE) Filter Bags: Industrial-Grade Filtration Solutions

- Operating range: -4°F to 266°F (-20°C to 130°C)

- Consistent filtration efficiency across temperature range

- Suitable for elevated temperature applications

- 5-line needle stitched design with thermal treatment

- Reliable sealing characteristics

- Structured for operational stability

- Effective performance under standard pressure conditions

- 5 standard size options

- Flow rates up to 40 m³/h (Size #2)

- Maximum filtration area of 0.5 m²

- Optimized dimensions for efficient operation

- Micron ratings from 0.1 to 500 μm

- Reliable particle retention

- Maintains specified flow rates

- Adaptable to multi-stage filtration requirements

- Tested compatibility with acids and alkalis

- Abrasion resistant construction

- Verified performance in chemical processes

- Low fiber release characteristics

Industry Applications

FAQs

How do I choose the right filter bag for my application?

Consider these factors:

- Process fluid characteristics

- Operating temperature range (-4°F to 266°F)

- Required filtration level (0.1-500 μm)

- Flow rate requirements

- Chemical compatibility

- Housing specifications

- Pressure conditions

- Regulatory requirements

What makes the 5-line needle stitched construction superior?

Benefits include:

- Enhanced sealing efficiency

- Better pressure handling

- Reduced risk of bypass

- Improved structural integrity

- Extended service life

- Consistent performance under varying conditions

What factors affect filtration efficiency?

Key factors include:

- Particle size distribution

- Flow rate

- Fluid viscosity

- Temperature

- Pressure differential

- Contamination level

- Maintenance practices

- Filter media condition

How do I optimize filter bag performance?

Best practices include:

- Regular monitoring of pressure differential

- Proper installation procedures

- Adherence to flow rate specifications

- Regular maintenance schedule

- Correct housing installation

- Proper venting procedures

- Clean changeout practices

What are the signs that a filter bag needs replacement?

Monitor these indicators:

- Increased pressure differential

- Reduced flow rate

- Breakthrough of contaminants

- Visual inspection results

- Operating time limits

- Process quality changes

- Regulatory requirements

What's the proper storage procedure for unused filter bags?

Recommended storage conditions:

- Clean, dry environment

- Room temperature

- Away from direct sunlight

- Original packaging

- Protection from moisture

- Avoid chemical exposure

- Regular inventory rotation

What chemical compatibility factors should I consider?

A: Important considerations:

- Process fluid composition

- Operating pH range

- Chemical concentration levels

- Temperature effects on compatibility

- Expected exposure duration

- Cleaning chemical compatibility

- Material degradation risks

How does temperature affect filter performance?

Temperature impacts:

- Material strength

- Sealing effectiveness

- Flow characteristics

- Chemical resistance

- Service life

- Filtration efficiency

- Pressure handling capability

What are the proper installation procedures?

Key steps include:

- Clean housing inspection

- Proper ring seating

- Correct orientation

- Proper venting

- Secure closure

- Leak checking

- System pressure testing

How can I maximize cost-effectiveness?

Optimization strategies:

- Proper size selection

- Correct micron rating choice

- Regular maintenance

- Optimal changeout timing

- Process optimization

- Proper handling procedures

- Quality monitoring

What are special considerations for food & beverage applications?

- FDA compliance requirements

- Sanitary handling procedures

- Documentation needs

- Cleaning protocols

- Material certification

- Change-out frequency

- Quality control measures

How do different industries typically use these filters?

Industry-specific applications:

- Water Treatment: Pre-filtration, processed water

- Chemical: Product filtration, catalyst recovery

- Food & Beverage: Final product filtration

- Industrial: Process fluid cleanup

- Automotive: Paint filtration, coolants

- Electronics: High-purity water filtration